0 items

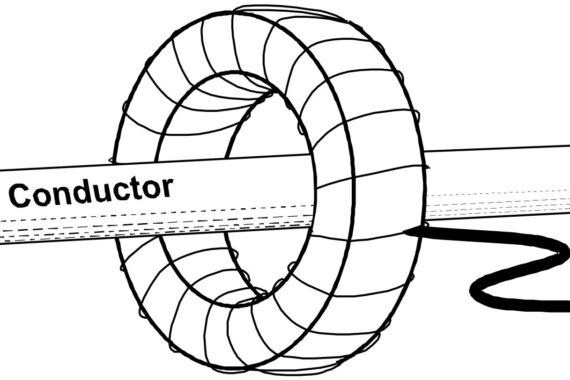

Applications of Rogowski Coils

One of the best ways to appreciate the versatility of Rogowski coil transducers is to consider the very wide range of applications that they have been used for. All the examples given here are based on real applications.

Rotating Plant

Measuring starting transients of electric motors

Rogowski coils were used to measure the current waveforms during the start-up of some large electric motors. The coils were used because they had good transient-measuring capabilities. The coils were easy to fit as a temporary installation inside a fuse box.

Split-phase current measurements in generators

The individual phase windings of a generator are sometimes made up of two half phases connected in parallel. Measurements of the two separate half-phase currents can provide useful diagnostic information about the condition of both the rotor and the stator. Rogowski coils can be mounted without disturbing the stator windings and are sufficiently compact to be retro-fitted even though the windings were not originally designed to accommodate split-phase measurements.

Sudden short circuit testing

Sudden short circuit tests are used to measure generator time constants. This information is needed to calculate how the generator will respond under transient conditions. The usual method of measuring the short-circuit currents is to use a resistive shunt. A Rogowski coil transducer is much easier and cheaper to install than a shunt, it is probably more accurate and is less likely to interfere with other engineering work taking place at the same time. A Rogowski coil has excellent transient response capability and can measure the ‘DC offsets’ which are associated with the short-circuit transients.

Protection system for slip-ring induction motors

Large slip-ring (wound rotor) induction motors are used in power stations to pump boiler feed water. A Rogowski coil has a good low-frequency capability and can be used to monitor the rotor circuits where the current flows at a slip frequency of about 1Hz. These measurements can be used to check the performance of the motor regulator and can be incorporated into a protection system monitoring phase imbalance and earth faults.

Measuring the currents flowing in the framework of a large generator

These measurements were made as part of a research investigation into the causes of hot spots and other localised overheating in large generator stators. Flexible Rogowski coils were used to measure the currents which had been induced in the stator support framework by leakage magnetic fields from the stator core. Rogowski coils were used because they could be fitted round ‘odd-shaped’ conductors in places where there was only a small amount of space.

Shaft Current measurements

Long, flexible Rogowski coils have been used to measure currents flowing along the shafts of large turbogenerators. Shaft currents can be the cause of problems such as excessive bearing wear.

Monitoring a motor control centre

More than 100 Rogowski coils were installed to monitor currents in a large motor control centre (MCC) for a sewage works. Rogowski coils were preferred because they were easy to install in the compact busbar system of the MCC. Because of limited space in the busbar system it would have been very difficult to install conventional current transformers.

Static Plant

Fault testing on Uninterruptible Power Supplies

Measurements were made on some high-power Uninterruptible Power Supplies (UPS) which

provided emergency back-up in a nuclear power station. The current output from the supplies was monitored during a change-over to emergency backup to determine if there were any discontinuities in the current waveform which could adversely affect equipment in the power station.

Energy management measurements

Flexible Rogowski coils are widely used for energy management measurements because they can easily be fitted around the conductor being measured even if there is only a limited amount of space round the conductor.

Precision calibration of current transformers

A technique has been developed using Rogowski coils so that current transformers can accurately be calibrated on-site without the need to remove them to a calibration laboratory. This would be useful, if a current transformer had been damaged in service, for example by a fire, to test if it was still working correctly.

Monitoring the ripple in battery chargers

Rogowski coils are able to measure a small alternating current which is superimposed on a large DC component. This is because they contain no iron and are not subject to saturation problems as with a conventional current transformer. Similar measurements have been made on the ripple component in the excitation of a generator rotor.

Measuring currents in rectifier systems

a) Rectifier systems providing large DC supplies frequently use several diodes or thyristors in parallel for rectification. If one of the diodes or thyristors fails this will not necessarily cause failure of the complete rectifier system but it places an additional strain on the other rectifiers which are in parallel with it leading to early failure. By monitoring individual rectifier currents failures can be detected and repaired before they lead to a catastrophic failure. Rogowski coils are good for this application because they can be retro-fitted when space is limited. Coils have been designed to fit round disk-type thyristors.

b) Rogowski coils cannot be used to measure DC directly but they can be used to measure AC currents supplying the rectifier system and, by using a simple circuit, the DC current from the rectifier can be constructed. This is a surprisingly accurate method of measuring large DC currents. The technique has been used to measure generator rotor currents and currents in a high-current DC supply intended for aluminium production.

Measuring power including low power factor situations

Rogowski coils can make accurate current measurements with a low phase error and consequently they are useful in power measurements especially when phase accuracy is important. A particular advantage of a Rogowski coil is that the accuracy is maintained even in a ‘clip-on’ device. Clip-on current transformers are notorious for errors, especially phase errors, if the mating faces do not fit together perfectly. A Rogowski coil is much less sensitive to errors caused by misalignment of the ends.

Monitoring current transformer secondaries

In some current transformer systems, especially those concerned with metering, it is most important that the secondary circuits are not disturbed. Rogowski coils can be used to monitor the secondary currents without the need to make any disconnections. Using a Rogowski coil ensures that no additional impedance is ‘reflected’ into the secondary circuit.

Arc furnace currents

Several systems have been supplied for measuring the electrode currents in arc furnaces. A flexible Rogowski coil is a compact and economical transducer for measuring very large currents.

Transmission Plant

Tracing earth faults in large and complicated conductor systems

This was an interesting project where an earth fault had been detected in the main output connections of a large generator. The generator could not be used until the fault was traced. The conductors involved were very large (more than 1metre in diameter). Using a long flexible Rogowski coil, the fault was traced in less than an hour. It was caused by a badly fitted insulating washer inside a circuit breaker. It is difficult to see how this fault could have been found otherwise without dismantling the entire output connection system.

Generator Main output connections

The enclosures round the main output connections can be more than 1 metre in diameter. A long flexible Rogowski coil can be used to measure the current in these connections. This ability has been useful in several applications.

a) Temporary monitoring of the generator output.

b) Monitoring currents during very large current overload tests which were designed to check whether the output connection system would safely survive a close-up short circuit (ie. on the generator side of the output transformer).

c) To check the integrity of the output connections following the major failure of a generator output transformer.

Current sharing in parallel conductors

Flexible braids are used inside generators to provide a conductive path where vibration would cause the fracture of a rigid conductor. Often large numbers of these braids are connected in parallel and it is important that the current is distributed evenly between individual braids. Rogowski coils are a good way to check the currents in the individual braids because they do not add any impedance to the conductor being measured. If a clip-on current transducer is used the presence of the CT reduces the current in the braid being measured.

Measuring induced currents in the steel-work around a transformer

Currents flowing in the cooling pipework of a large transformer were causing heating at bolts and flanges. A flexible Rogowski coil was used to trace the currents and monitor the effectiveness of a remedy.

Measuring the earth resistance of a transmission tower

For safe operation of a grid system it is important that the transmission towers are correctly earthed. It is difficult to check the earthing of an individual tower because all the towers in a line are earthed together. Long flexible Rogowski coils can be wrapped round each leg of a tower to measure the current flowing to earth when a voltage is applied between the metalwork of the tower and earth and hence the resistance can be calculated. With this technique it is possible to measure the resistance of individual tower legs or, by summing the currents electronically, to measure the overall earthing resistance.

High-current testing of switch-gear and fuses

Rogowski coils provide an extremely compact transducer for measuring currents of several hundred kiloamps that are sometimes needed for switchgear and fuse testing. Unlike a conventional current transformer they have a very good transient response. Also they can be designed to respond to very low frequency currents and are able accurately to reproduce the ‘DC offset’ currents that occur with AC transients.

Measuring leakage currents down insulators

Rogowski coils were used to measure the leakage down some high voltage insulators. Rogowski coils were used rather than resistive shunts to provide isolation. The currents were very low (a few microamps) and it was necessary to use rigid coils, which are more sensitive than flexible coils, with a large number of primary turns.

Earth leakage currents

A coil can be positioned round all three conductors of a three-phase system simultaneously. In a healthy system the total current should be zero. A non-zero total current indicates an earth leakage.

Pulsed Power

Measurements with lightning test equipment

Rogowski coils are used routinely to measure currents during tests to determine the effect of lightning on, for example, aircraft components. The current in a lightning strike can be typically 20kA rising in a few microseconds.

Weld-current measurements

Rogowski coils have been found useful for measuring currents during welding processes. This helps to make the welding process more reproducible. The coils used can be made very compact and easy to fit.

Measuring the current in Electromagnetic Launchers (rail guns)

A rail gun is an electromagnetic method of launching a projectile. The current required is typically a few million amps lasting for about a millisecond. Rogowski coils are ideal for this application. In general the larger the current the smaller the Rogowski coils needed to measure it. The measuring system for a rail gun only weighs a few hundred grams!

Railway Applications

Monitoring the current in railway lines to check signalling currents

Signalling currents flowing down railway lines are a very important part of railway safety because they are used to detect the presence of a train on a section of track. Bad joints and other faults can interfere with these currents and may result in the shutdown of a section of the rail system for safety reasons. Flexible Rogowski coils can be used to measure currents in the actual track and speed up the detection of faults. A special rail-current monitor has been built which enables this measurement to be made quickly and with suitable filtering it is possible to detect signalling currents of much less than 1amp in the presence of a traction current of several hundred amps.

Monitoring the traction current drawn by a locomotive to ensure that the power systems

do not produce frequencies that interfere with the signalling system

When locomotives are fitted with variable-speed drives there is the possibility that the drive electronics can create small currents at the same frequencies as the signalling currents and cause signalling errors. The current between the locomotive and the rails is monitored to ensure that harmful frequencies are not present. A Rogowski coil is good for this application because it is completely linear and with suitable filtering techniques it is possible to extract information about currents at specific frequencies even in the presence of large traction currents. Large numbers of detection systems using this principle are in use.

Operating Limits

Share this page